Shade Saqils With Posts and a=hardware

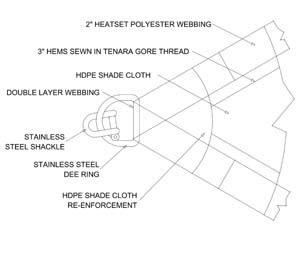

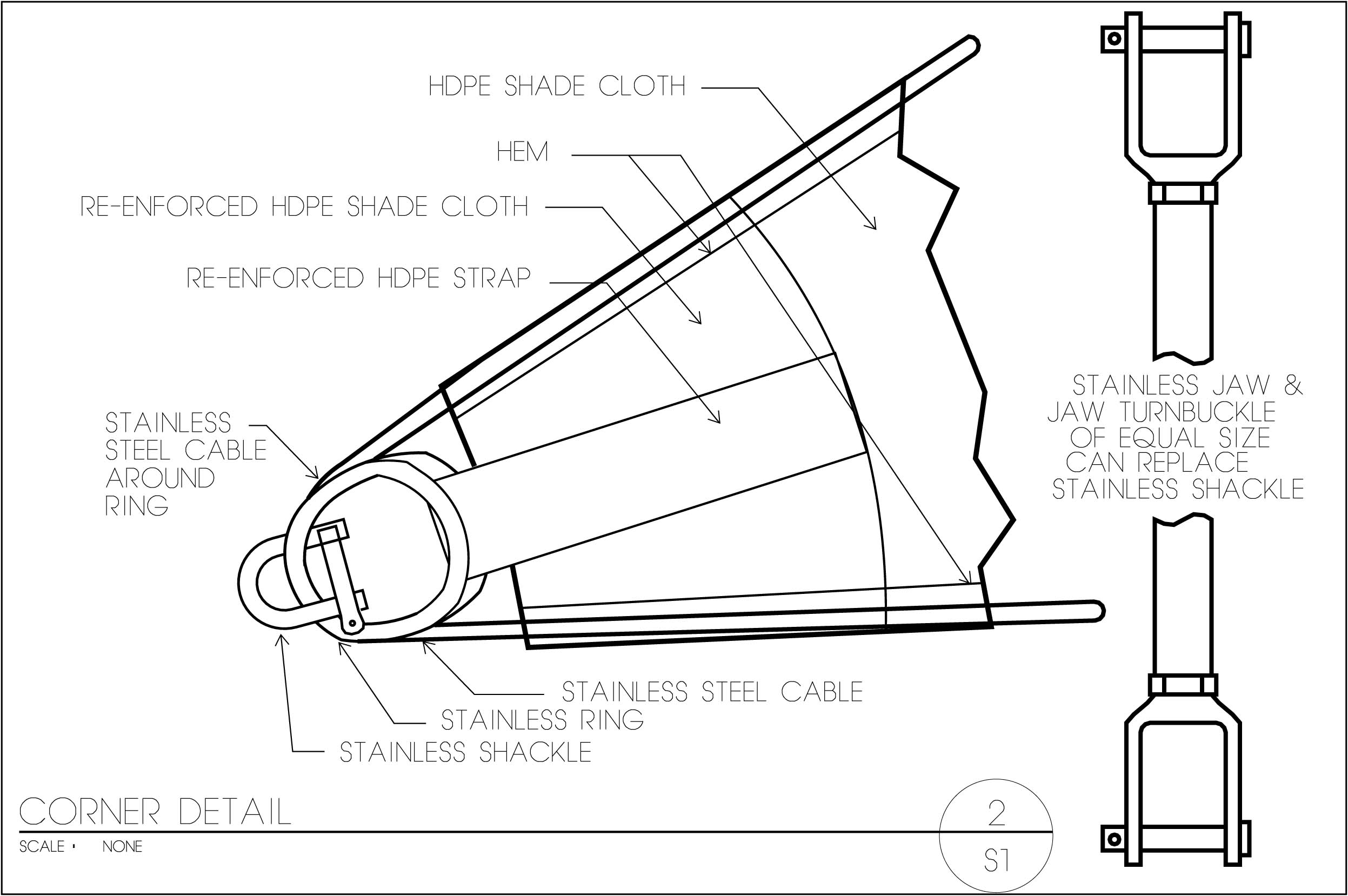

2 Types of constructions available: (A) Commercial quality with "Webbing reinforced" type construction in custom sizes and colors. Sewed with "Solar Fix" thread. These are only as strong as the cabled sails and easier to install. In most cases we adopt our customers to use these type. (B) Commercial quality with Stainless steel cabled perimeter and extra reinforcement. Made to fit the space. Requires some skill during installation. Continuous cablevision with clamps Sewed with "Solar Fix" thread. Continuous cabled sails often require extra "D" shackles to fit their larger corner rings. Why do a Custom Sheet?

- They can be made in almost any shape which allows for more than design creativity. (meet design parameters)

- They are easier to install considering they are made to fit the space not the other fashion effectually. This ways less messing effectually with hardware pieces trying to go them to fit. Just measure from fixing point to fixing point and the sail is made to fit.

- Custom sails are fabricated to commercial quality standards which are much stronger and more than durable.

Why our Shade Sails are the all-time? To reach that taut tensile fabric look, you lot need to kickoff out with a sail that is properly fabricated and installed correctly. Don't be fooled by catalog sails that hang limp. These Shade Sails are not available anywhere else. Also, look at the hardware "they" offer, and so look at ours. Our hardware is intended for tension loads and is load rated. Theirs are intended for a picnic. We have pull tested our sails at over a ton of force. Combined with our "load rated" hardware the systems we offer are designed to give you a trouble free installation. These are serious tensioned-fabric structures non a picnic tarp!! We are confident that these are the best quality and strongest Shade Sails on the market today.

- Our Custom Sails are made with "Monotec" 370 brand fabric. This is the strongest and best Quality HDPE Textile on the market place. No other gear up-made on the market comes shut.

- Monotec 370 fabric – Has round mono-filament fibers which means it stays cleaner and is easier to make clean. All monofilament with no tape filler is 3 times stronger than mono/tape type fabric. It's positive memory yarns crave no re-tensioning. Monotec 370 is made in Australia, not China or Indonesia.

- Shadetex is also a fabric option which is bachelor in 10' wide rolls. It is a footling less expensive and is appropriate for smaller sails (less than sixteen′ edges)

- Ultra potent Marine Class Stainless Steel Corner Rings.

- We utilize a Double Row of Locking Run up (Not a concatenation sew together used by our competitors.)

- Our Custom Sails are sewn with Solar Set up thread that is warranted for over 10 years against UV breakdown. This thread cost 100X more than normal Dacron Polyester. But skimping on thread quality is what most our competitors exercise.

- Heavy Duty Polyester (seat belt) webbing reinforced edges and corners. No need for added cable. (We also offer cablevision reinforced sails.

- Installed properly to a well engineered structure, these sails can withstand 85 mph winds.

See Custom Fabrics ..click here.. GET A QUOTE OR ORDER(click hither)…Our unique automated quote/ordering system makes it easy to get our all-time pricing and helps forestall issues like transcription errors. Simply enter your dimensions on this on-line form to get a quote or get all the way to the terminate to gild a custom sail. The automated class also prompts y'all through the process which speeds upward getting a custom sail past days. Custom Sails Order Form

The Nuts of Custom Shade Sails

All our community sails include Gratuitous Aircraft. Nosotros offer two options. ane) (Recommended) The Custom Sail includes turnbuckles and shackles and is adjusted to fit the space. Or 2) The sail is just Made To the Dimensions you provide. This option does not include any hardware.

Option 1….The Recommended Process:The fixing points (eye-bolts or Pad-optics) should be installed kickoff (not included) . Then measure and the sheet is then made to fit

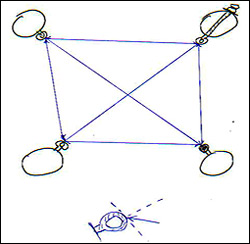

For the a Custom Sail made to fit your space…includes turnbuckles + shackles and is adjusted to fit the space. Shade Sails are made to fit very accurately to their zipper points. Therefore it is important to follow these instructions: 1) Plan your installation. Check with your local building Dept. Many installations crave a building permit. We are not responsible for obtaining permits or for technology your installation. 2) To Aid you lot visualize the Sails, y'all can use string stretched between your planned attachment points. Think the sail practise non have straight lines at the edges, they are constructed with a gentle curve that deflects about 10% over the length of each edge. Nosotros have found the best looking installations take bold changes in height from i corner to the next, and that overlapping sails or multiple sails give a more interesting look. As well, please ensure you have a 25% gradient (1:iv departure from lowest to highest point) to ensure h2o run off 3) The zipper points should be installed first. Then the sails are made to fit. Therefore, install your posts with centre bolts, plates, eyes or straps to the house, tree or whatsoever you take chosen to support them. Call back, at that place can exist substantial wind loads. (from 10 to 18 lbs. per foursquare pes of sheet). The sails have stainless wire or heavy webbing around their perimeters and can handle high wind loading. These loads are divided between the corners, but it is important that what they attach to be adequate for the loads they tin can produce. For our posts, we usually kickoff with iv″ schedule 40 steel pipage (galvanized) or temporary power poles (treated) that are 6″ or larger for our posts. They are usually embedded in a concrete footing, 3 ft. to 6 ft. deep and i ft. to 1.5 ft. in diameter. As the sails go larger or college then the post size should be larger. We tin can provide engineering services (for a fee) to determine these details. Corners of buildings are excellent attachment points and we have designed a special corner clip for that application (come across hardware page). Besides, it is often possible to connect to remote structures with wire spanning the distance only this should merely exist used to extend 1 corner of the sheet whatsoever significant altitude. four) The sails accept a stainless steel ring at each corner that must be attached to your fixing signal. This can exist done in a diverseness of means; the best method is to use "D" shackle and turnbuckles. When you lot have your measurements we will make recommendations every bit to what attaching/tensioning hardware to use and their locations. v) Measure accurately from the outer edge of the middle of one attachment point to the side by side. On four sided sails we need diagonal measurements every bit well. Also supply united states with the heights of the fixing points. 6) Cull a colour With the made to fit your space option nosotros supply the marine grade stainless steel shackles and turnbuckles to attach the sail to the fixing points or eyes.. Therefore it is essential you utilise our eyes or fixing hardware then that we tin can be sure that our turnbuckles etc. fit onto the eyes without actress pieces.

Measuring For Option 1… A Custom Shade Canvas Adjusted And Fabricated to Fit The Infinite:

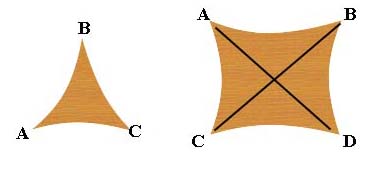

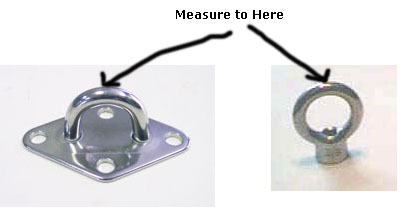

To insure proper fit of a custom sail you lot must follow the directions. Measurements should exist to the nearest inch. (round down) Start, you accept to install the fixing points (eyes). Estimating their size and location is not enough and will result in a bad fit. This means the posts must be in the basis and their optics or fixing points installed. Use our hardware. Using other hardware can oft create issues with compatibility. The hardware nosotros sell is compatible with each other. That is the turnbuckles, shackles and optics all fit together and are also sized with similar load ratings. If you apply a non-compatible component yous may demand additional components to "span the two and this will besides cause a misfit. Using welded pad-optics can be accommodated, but specialty shackles (long or twisted) may need to be added, normally calculation to the toll. To guarantee proper fit, you need to measure the space the Shade Sail and hardware will occupy. That is to say the space between the fixing points. Therefore, measure out from the exterior of each eye at its noon that faces the center of the canvass. Do not… measure from inside the heart or the face of the mail service!! If you are doing a 4 or more sided sail then we need diagonal measurements also. More often than not, 2 turnbuckles on triangles and 2 on quadrilaterals are used on custom sails, which are included with the canvass. The other corners are connected with a "D" or twist shackle.. We compensate for the size and location of the included turnbuckles and shackles. (Not yous) Measure Each Dimension Per the Sketch Below:

MEASUREMENTS: (mensurate from the outside of the center at the indicate closest (apex) to the center of the shade sail) Enter edge dimension in inches Triangles A-B B-C A-C For Quads A-B B-D C-D A-C Diagonals for quads (required). A-D C-B More often than not nosotros use 2 turnbuckles on triangles and 2 on quadrilaterals which are included with the sail when you choose the Adjusted and made to fit option. The other corners are connected with a "D" shackle.. We compensate for the size and location of turnbuckles and shackles. (Not you) GET A QUOTE OR ORDER (click hither)…Our unique automatic quote/ordering organization makes it piece of cake to get our best pricing and helps prevent problems like transcription errors. Just enter your dimensions on this on-line form to get a quote or go all the way to the cease to order a custom sail. The automatic course also prompts yous through the process which speeds up getting a custom sail by days. Custom Sails Order Course

MEASUREMENTS: (mensurate from the outside of the center at the indicate closest (apex) to the center of the shade sail) Enter edge dimension in inches Triangles A-B B-C A-C For Quads A-B B-D C-D A-C Diagonals for quads (required). A-D C-B More often than not nosotros use 2 turnbuckles on triangles and 2 on quadrilaterals which are included with the sail when you choose the Adjusted and made to fit option. The other corners are connected with a "D" shackle.. We compensate for the size and location of turnbuckles and shackles. (Not you) GET A QUOTE OR ORDER (click hither)…Our unique automatic quote/ordering organization makes it piece of cake to get our best pricing and helps prevent problems like transcription errors. Just enter your dimensions on this on-line form to get a quote or go all the way to the cease to order a custom sail. The automatic course also prompts yous through the process which speeds up getting a custom sail by days. Custom Sails Order Course

Fabric FOR CUSTOM SHADE SAILS See Custom Fabrics ..click here..

Need Advice? Not all shapes or sizes will requite good results. Contact us if y'all need communication.

Notation, Custom Sails larger than 80′ around the perimeter are merely warrantied against flaws in workmanship and materials for one year. Sails with perimeters greater than eighty′ around are not warrantied for any specific life bridge or longevity. Meet warranty information for more details. (Custom sails commonly take almost 2-3 weeks)

0 Response to "Shade Saqils With Posts and a=hardware"

Post a Comment